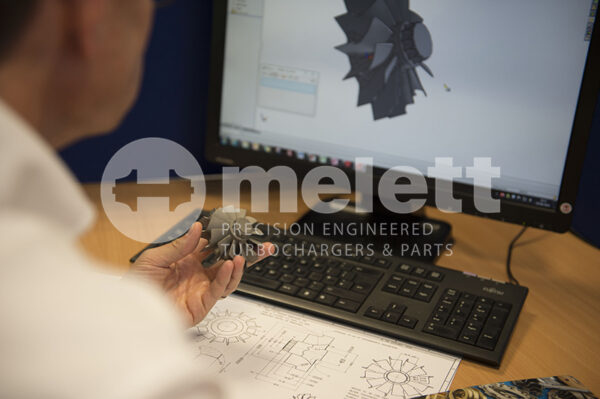

It is a well-known fact that many companies make false claims that they manufacture parts for OEM’s and Melett. Due to Melett’s growth and the Melett brand being recognised as the trusted aftermarket brand for quality, this became a more obvious issue for the company. In reality these false claims cannot be justified, and here’s why…