A year on from the Volkswagen emission scandal, speculation is growing about the life-span of diesel engines, fuelled by rumours that Norway is planning to ban all diesel engine passenger cars by 2025 – with other European countries potentially following suit. So do diesel passenger cars have a future? And how realistic is it to carry out such schemes? What impact will the elimination of diesel passenger cars have on the turbo aftermarket?

CO₂ emissions impact the atmosphere and are continuously reported as a key contributor to climate change. The more recent focus on passenger car emissions has been accelerated by the Volkswagen scandal of 2015. The aftermath revealed there was a huge difference between the results of OEM laboratory tests and real-world driving emissions.

As a result, New European Drive Cycle (NEDC) legislation has been revised in line with real-world driving conditions. This has highlighted that European institutions are trying to get a better understanding of emissions from diesel and petrol cars.

Improving air quality

In a bid to improve air quality in Norway, leading political parties have called for a ban of the sale of all diesel passenger cars by 2025. In contrast, the UK government has set policies in place to push low emission vehicles – which includes diesel passenger cars. It would be much more difficult to implement an outright ban in the UK. The population is considerably larger, with a larger diesel passenger car parc.

Despite a push on low emission vehicles, air pollution remains a hot topic in the UK. As the country prepares to leave the European Union there needs to be clarity on what is going to happen to current air pollution policies. When the government pushed diesel cars in the early 2000’s, they knew there would be a negative effect on air pollution. But, they believed it would be vastly outweighed by the reduction in greenhouse gas emissions.

As technology advances, zero air pollution and zero emissions should, in hindsight, become easier to achieve. The current political focus appears to be on rectifying the current situation through the regulation of existing technology such as diesel particulate filters (DPF) or selective catalyst reduction (SCR) technology.

Benefits

There are many benefits to diesel engines. It has been well publicised that today’s diesel passenger cars are the cleanest ever, with high tech filters capturing 99% of particulates. Since the introduction of the Euro emission regulations in 1992 diesel particulate matter has reduced significantly and is currently at the same level as petrol applications at 0.005 g/km. NOx emissions have also significantly reduced and are just 0.02 grams behind petrol passenger cars.

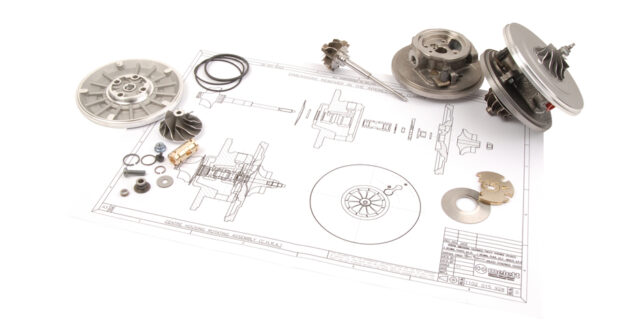

Overall, diesel engines are more efficient to run and contain more energy per litre than petrol engines. Diesels have led the way in turbocharger technology, with petrol applications now quickly following suit. Despite these positives, the Norwegian national parliaments are committed to the ban of diesel passenger cars. They currently lead the way in electric vehicle sales due to tax exemptions, free charging points and parking benefits.

The ‘demonisation’ of diesel

Since the Volkswagen scandal diesel passenger car sales have seen a downward trend; the Group’s Audi division has seen their market share drop from 69% to 67% in the first four months of 2016. Consumer research suggests the scandal has been a major contributing factor in this downturn. Buyers are seeking out petrol applications that match the performance and fuel efficiency of their diesel counterparts, as well as hybrid and electric vehicles.

Although diesel is often in the firing line, it isn’t just these cars that create the problems; it extends to vans, buses, taxis and petrol engines too. For example, diesel road traffic is responsible for about 40 per cent of London’s NOX emissions. Government policies to reduce carbon emissions have indirectly promoted and incentivised the use of diesel over petrol. Which as lead to an increase in the number of diesel cars on the road.

With this in mind, countries calling for a ban of diesel cars need to consider other contributors to vehicle air pollution which are varied. Any new policies should consider the impact to these groups and the effect they will have on the automotive industry as a whole.

In terms of the turbo aftermarket, there are still plenty of turbochargers that will need repair. Due to the adoption of turbos on petrol applications, this will continue for many years to come.