Melett has expanded its turbocharger and component range with several major new releases during Q4 2025.

-

A key addition includes a HELLA electronic actuator for Toyota Avensis and RAV4 applications

-

Core assemblies have also been introduced for Cummins ISB 4.5D Euro 6 engine and Volvo 2.0D applications, including the XC60, XC90, S90 and V90 models

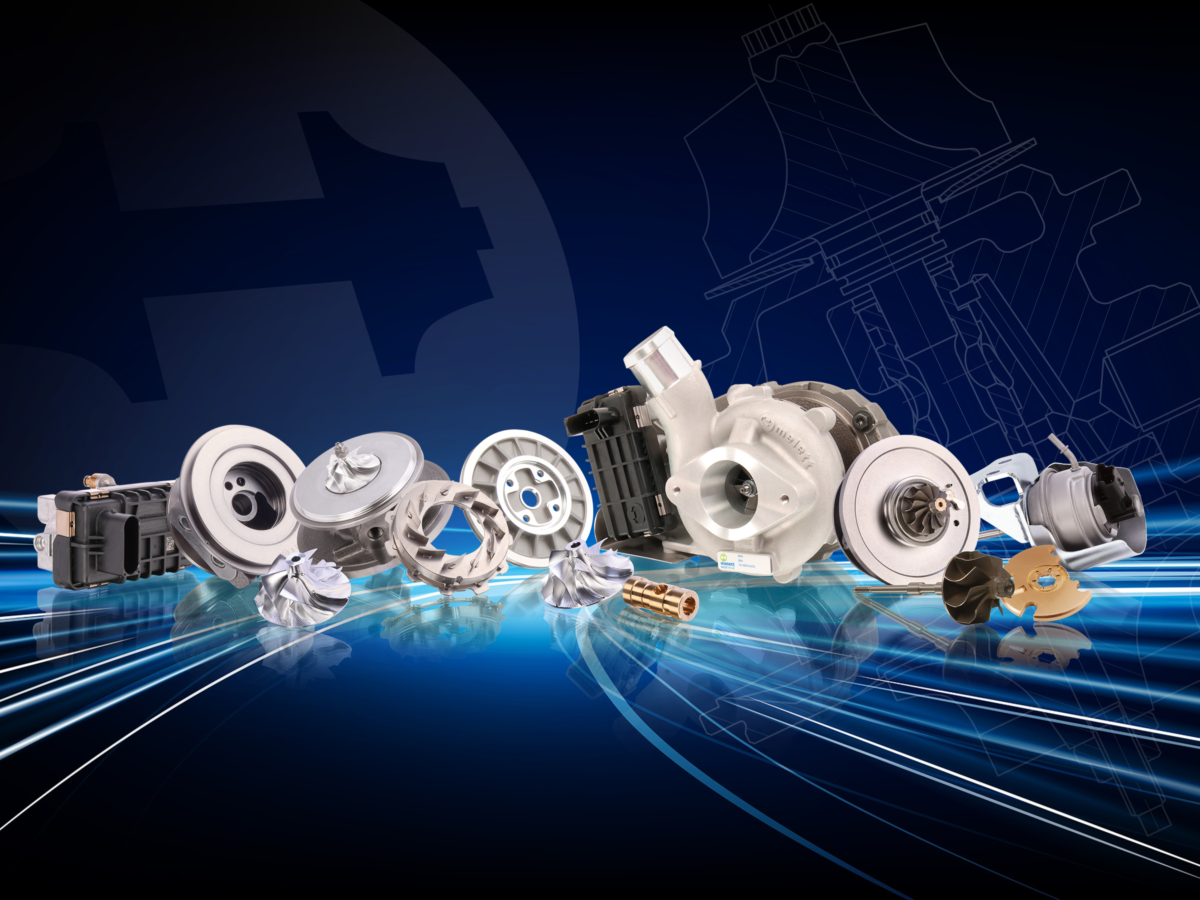

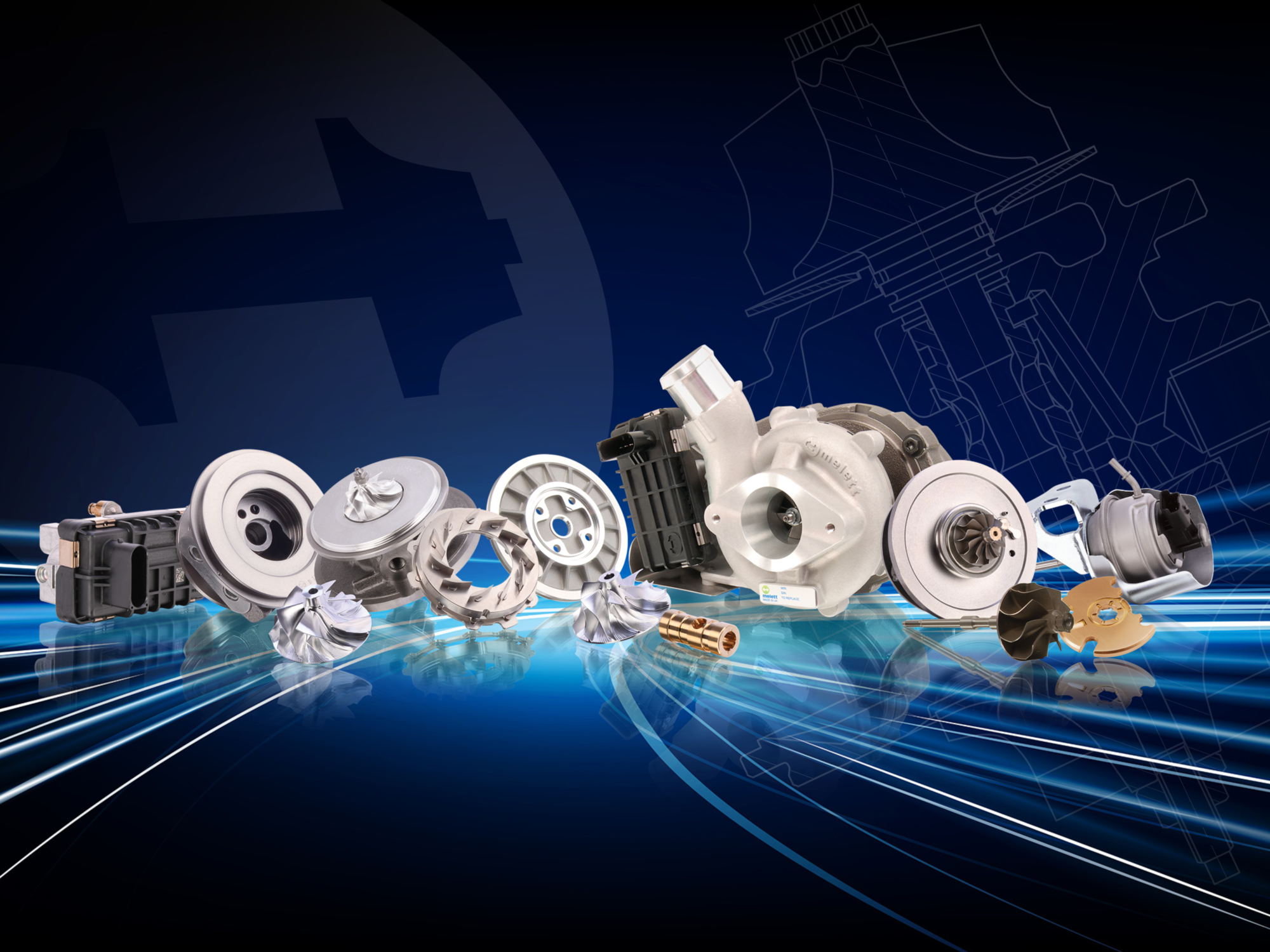

Melett, the leading global supplier of precision-engineered turbochargers and components for the global automotive aftermarket, has further expanded its product portfolio with a series of new turbocharger components launched for Q4 2025, strengthening coverage across both passenger car and industrial applications.

The latest additions include new CHRA units and a turbocharger actuator, designed to meet the growing demand for high-quality, OE-level replacement solutions across a diverse range of vehicle platforms.

One of the key releases is a new CHRAfor the widely recognised Cummins ISB 4.5D Euro 6 engine. The inclusion of this CHRA reflects Melett’s ongoing commitment to supporting commercial sectors. The Cummins ISB 4.5D Euro 6 platform is extensively used across a variety of on-highway applications, making reliable turbocharger components essential for maintaining uptime and performance.

Melett has also introduced a new CHRA covering Volvo 2.0D applications, including the XC60, XC90, S90 and V90 models. These vehicles represent a significant proportion of the diesel car parc, and the new CHRA provides turbocharger specialists with a dependable OE-quality solution for some of Volvo’s most popular premium models.

Further expanding its component range, Melett has launched a new HELLA electronic actuator for Toyota Avensis and RAV4 applications. As actuator technology becomes increasingly critical to turbocharger performance and emissions compliance, this addition supports workshops and turbo rebuilders servicing high-volume Japanese models.

All Melett turbocharger components are manufactured to meet or exceed original equipment (OE) specifications. Each CHRA is precisely assembled and VSR balanced in Melett’s UK and Polish production facilities, ensuring consistent reliability, durability and performance in demanding operating conditions.

The Q4 2025 product launches underline Melett’s continued investment in expanding coverage, providing turbocharger specialists with trusted, precision-engineered solutions backed by comprehensive technical support.

Garages experiencing suspected turbocharger issues are encouraged to seek expert inspection and diagnosis to identify the root cause of failure and prevent repeat issues.