The Importance of the Correct Material Specification

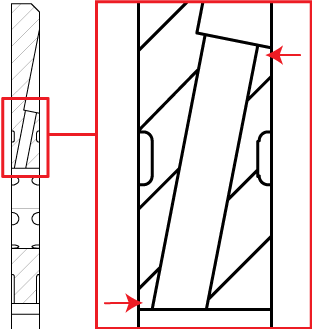

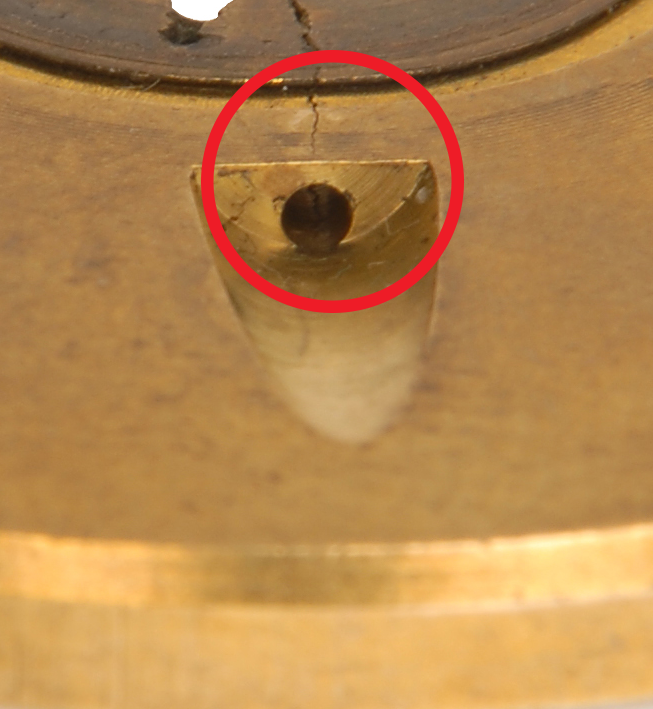

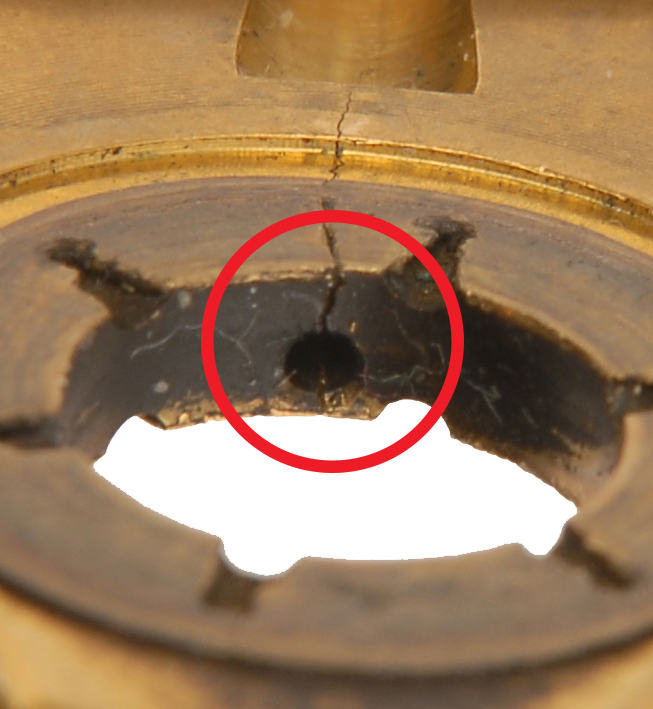

Critical Points – highlighted are the areas of the thrust bearing where it will crack if the material is too thin, the material specification is insufficient or the incorrect manufacturing processes are used.

![]() Is there enough material between the wall of the oil hole and the thrust face to withstand the thrust loading?

Is there enough material between the wall of the oil hole and the thrust face to withstand the thrust loading?

Sintering is a perfectly good manufacturing process for thrust bearings and is preferred by some turbo OEM’s, as the resulting porosity in the material gives it excellent oil retention properties reducing wear at cold engine start. Other manufacturers choose high strength materials to ensure long life and apply various specialist surface finishes to increase surface oil retention.

Importantly, each thrust bearing is designed accordingly to the physical parameters of the material. Sintered material has a lower tensile strength than stamped or hot forged materials. As a result, the wall thickness of a sintered thrust bearing is designed to account for the material strength and is usually thicker. This is to ensure that when the oil feed hole is drilled, there is enough material remaining between the wall of the oil hole and thrust face, to withstand the thrust loading and ensure the fatigue life is appropriate for the application.