Common turbo failure – oil leaks

What are oil leaks

Oil leaks can be caused by a variety of factors, the main factor being incorrect pressure within the compressor and turbine housings. Oil leaks can cause catastrophic damage to the bearing systems and occur within seconds of the turbocharger commencing operation.

When a turbocharger is installed correctly, it should NOT leak oil, however, there can be cases where oil leaks occur. The following highlights some of the main causes and signs of oil leaks.

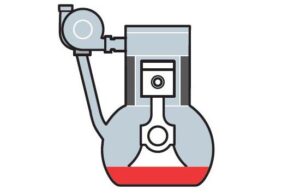

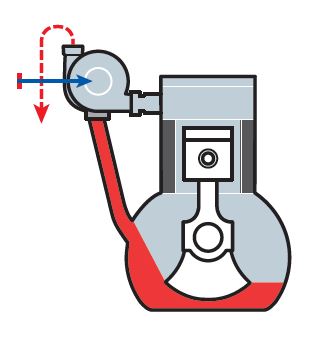

Example of correct pressures

The above diagram shows the correct oil pressure in both housings resulting in no leaks from the turbo.

PLEASE NOTE – An oil leak can also occur when engines are running on idle. The pressure within the housings is lower, which in turn can lead to a vacuum being created, causing the oil to leak into the turbine housing. Once the engine starts to run at normal speeds the pressures will be restored and the leaks will stop.

Causes of oil leaks

Compressor End

Poor quality old core

Intake hose splitting

Incorrect fitting of the intake pipe/hose

Blockages to the air intake pipe/hoses

Blockages to the air intake filter

Fitting the incorrect turbocharger

Incorrect pressure in the compressor end

Dirty air filter over time due to natural build up

Damaged or cracked compressor housing

Blockages in the exhaust system

Both Ends

Poor quality old core

Fitting the incorrect turbocharger

Physical damage to the turbo’s rotating parts and excessive bearing clearance (possibly caused by other failure modes)

Excessively high oil pressure

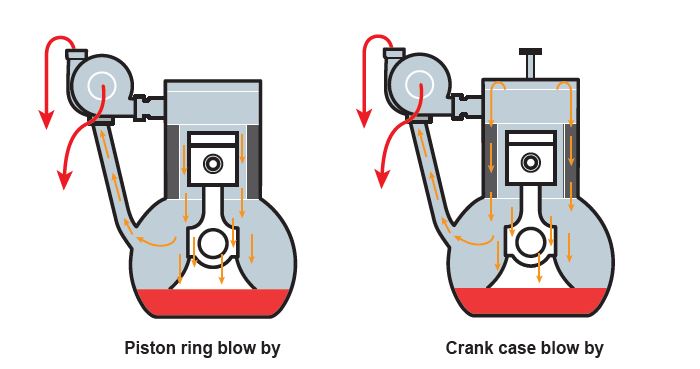

Excessive crank case pressure (blow-by from worn piston rings/bores)

Reused oil return pipes

Increased crank case pressure

Over filling of the oil

Use of silicon sealant / incorrect gasket

Repeated hot engine shutdowns leading to carbon deposits (coke) in the centre housing

Twisted, bent or trapped oil return pipe

Turbine End

Poor quality old core

Collapsed turbine piston ring from excessive EGT’s

Incorrect pressure in the turbine end

Leaks with in the exhaust system

Fitting the incorrect turbocharger

Poor quality gasket

Incorrect gaskets

Cracks in turbine housing, sometimes only visible when hot

Warped exhaust flange

Examples of how oil leaks can occur:

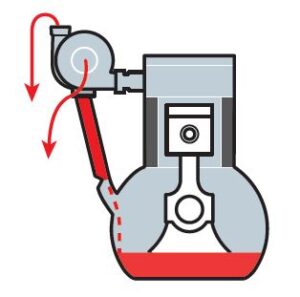

If there is a kink, bend, twist or partial blockage in the oil return pipe, this will cause the oil pressure to build up in the bearing housing, resulting in leaks from both turbine and compressor ends.

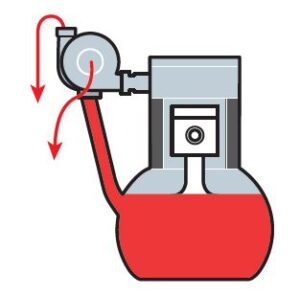

If the oil level is too full there will be nowhere for the oil to flow, causing a build-up of oil pressure in the bearing housing. This will cause oil to leak from both the turbine and compressor ends.

If the oil level is higher than specified by the engine manufacturer, the oil could to be forced back up to the oil return pipe with the motion of the crank, restricting the flow. This will cause leaks from both ends.

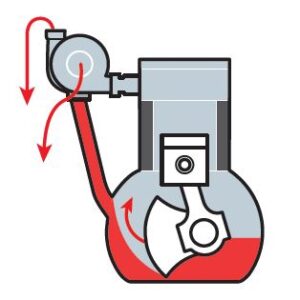

If there is a loss or increase of pressure in the compressor end or turbine end, this will cause oil leak in either the turbine or compressor end.

‘Piston ring blow by’ and ‘crank case blow by’ cause the same effect, they increase the pressure in the crank case. This affects the oil flow to the turbo at the correct rate needed and acts as a restriction to the oil return pipe, causing the turbo to leak oil in either of the turbine end or compressor end.

PLEASE NOTE – Oil leaks can occur on VSR (high speed) balancing machines as the ambient pressures required to create the seal are not present as no housings are used. This can then force out oil from both the compressor end and turbine end giving the impression of a leak. This is unlikely to occur when the replacement turbo is fitted to the engine.

Preventing oil leaks

- Ensure air and oil drain systems are clear from blockages or restrictions

- Check the exhaust system to make sure there are no leaks present

- Do not use silicone on oil gaskets as it can easily become detached and block oil passages

- Ensure DPF (diesel particulate filter) and Catalytic converter are free of blockages

- Use the correct gaskets and o-rings

- Only use the correct standard of turbine housings and compressor housings

- Check for correct oil levels and pressure