Insufficient Lubrication

What is insufficient lubrication?

If there is Insufficient Lubrication within the turbocharger the consequences can be severe. This is one of the most

common reasons for failure, a lack of oil in any of the lubricated areas can cause premature failure.

Insufficient Lubrication can result in catastrophic damage to the bearing systems which can occur within seconds of the turbocharger commencing operation. Quite simply:

- If oil levels are too low, the turbocharger will fail;

- If the wrong grade of oil is used, the turbocharger will fail;

- If oil becomes contaminated, the turbocharger will fail.

How does Insufficient Lubrication cause turbocharger failure? 🎥

Welcome to our latest Turbo Tips Video – Insufficient Lubrication.

Today we will be discussing causes, signs and preventions associated with Insufficient Lubrication.

What is Insufficient Lubrication? Insufficient Lubrication is one of the most common reasons why turbochargers fail. Oil is a vital component; it cools and

lubricates the journal and thrust systems of the CHRA. If there is Insufficient oil in these areas the CHRA is likely to fail.

Let’s look at some of the causes of Insufficient Lubrication.

Failure to prime the Turbocharger before installation.

Any damaged, bent or partially blocked Oil Feed Pipes.

And, never use silicone on the inlet or outlet as this will restrict the oil flow to the turbocharger.

A more in-depth list of causes can be found on our website.

Failure to prime the Turbo

Damaged Oil Feed Pipe

Never use silicone

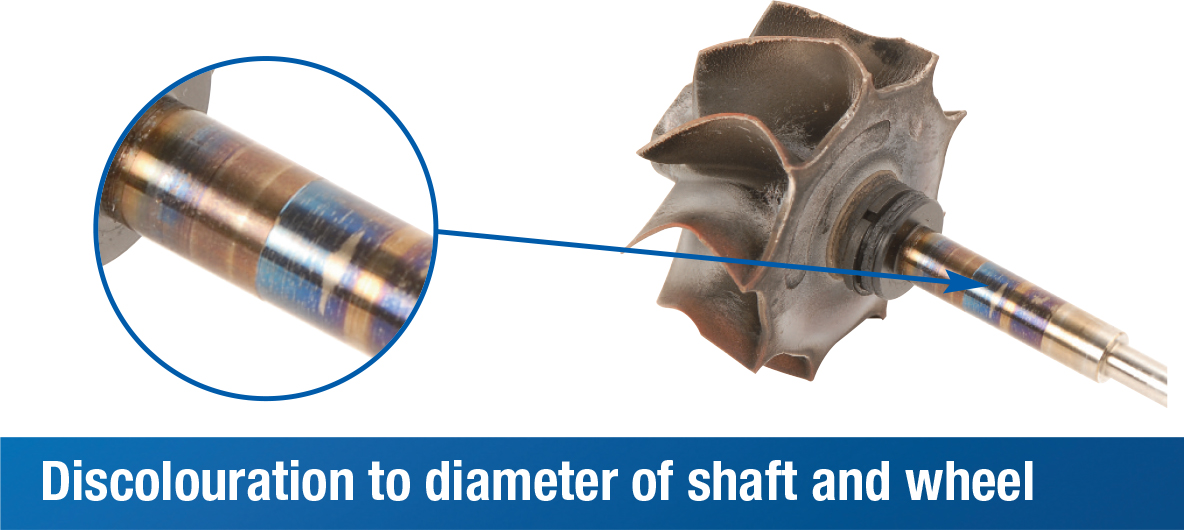

Let’s look at some of the signs of Insufficient Lubrication. Most of the damage from Insufficient Lubrication will be visible on the Shaft and Wheel.

Here you can see material transfer on the Shaft and Wheel landing areas.

The discolouration is caused by Insufficient Lubrication.

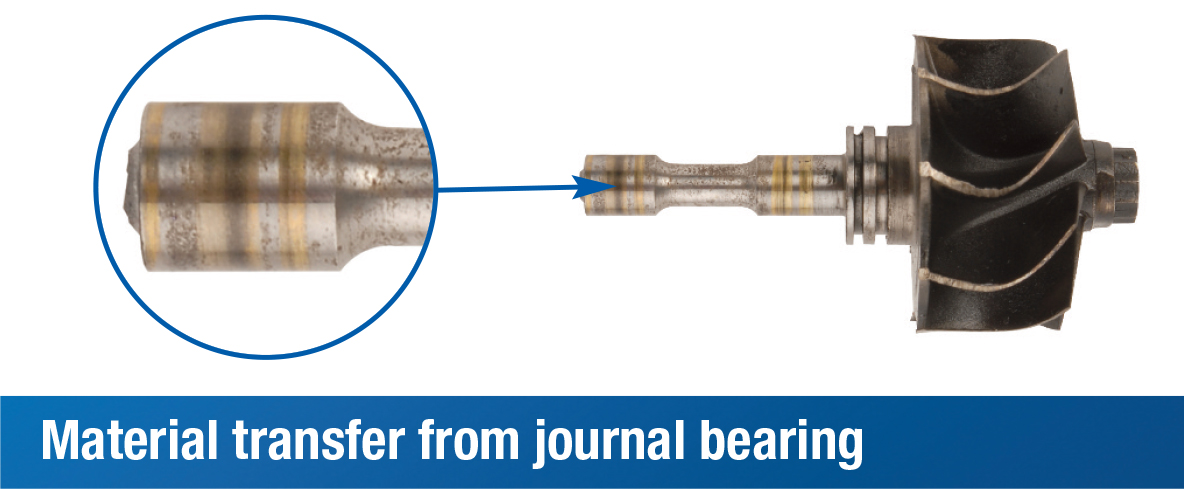

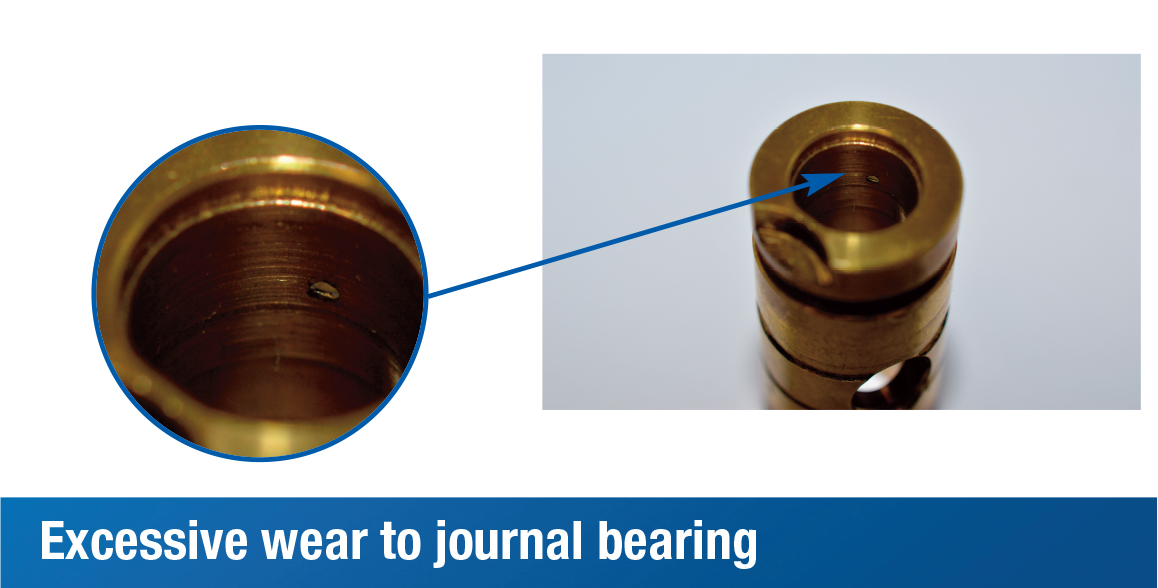

Signs of Insufficient Lubrication can also be found on the Journal Bearing.

On the ID of the Journal Bearing, we can see material displacement.

This could cause the oil feed holes to become partially/fully blocked, restricting the oil flow to the Shaft and Wheel.

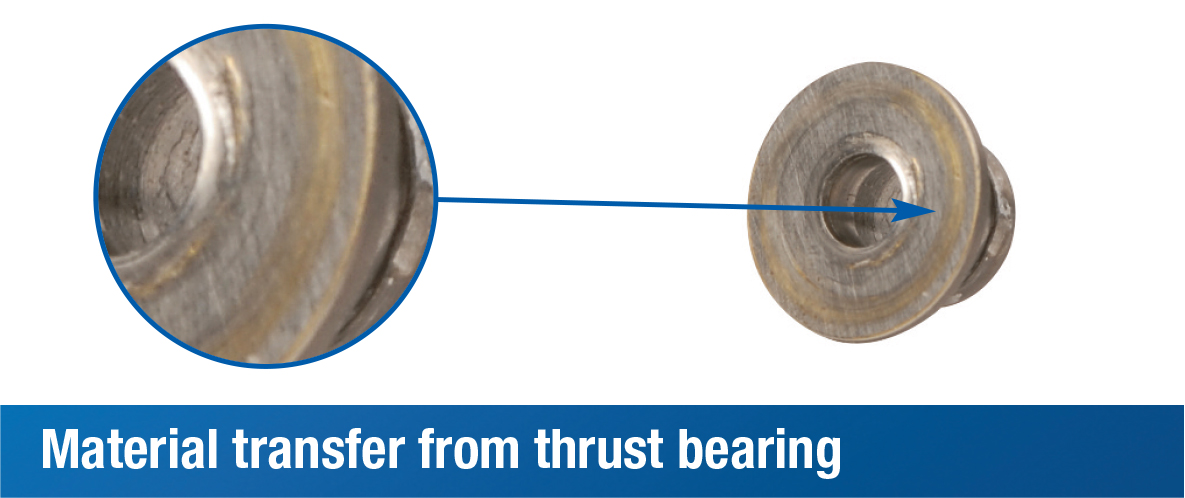

Next, we are going to look at the Thrust system: Thrust Bearing, Thrust Flinger, Thrust Collar and Thrust Washer.

Let’s look at these in more detail.

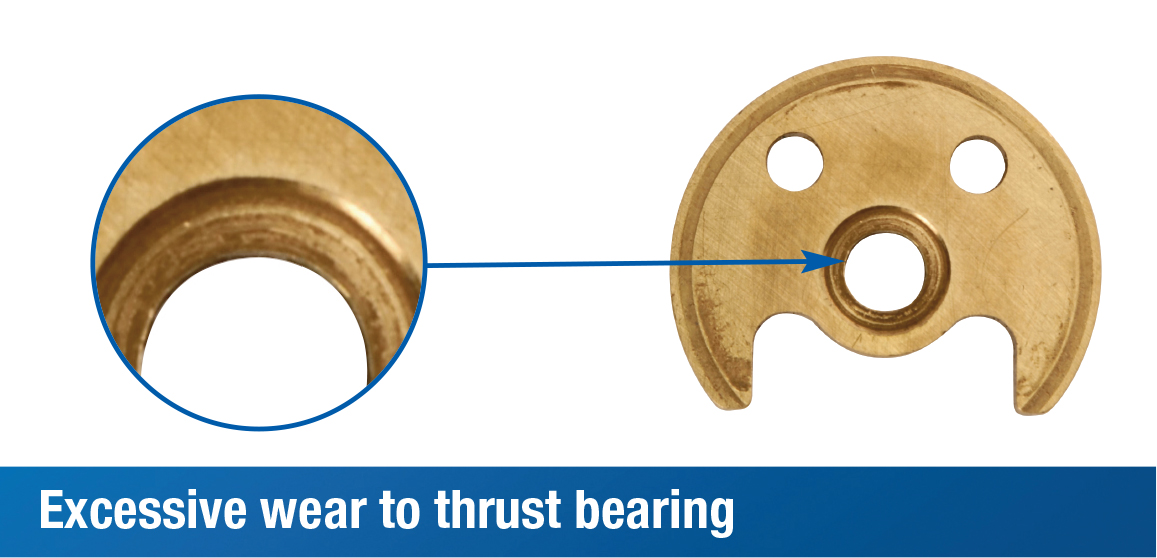

The Thrust Bearing will show signs of wear caused by Insufficient Lubrication.

Material transfer from the Thrust Bearing will be visible on the Thrust Collar, Flinger and Washer.

These are key indicators that a turbo has failed from Insufficient Lubrication.

We have discussed the causes and looked at the signs. Now let’s discuss how to prevent Insufficient Lubrication from occurring.

Always check the oil flow to the turbocharger and you have primed the turbo before installation. Never use silicone on the inlet or outlet and if possible new

fresh oil and a new oil filter.

For any more information, check out our PDF on the website.

Check the oil flow

Prime before installation

Never use silicone

Use fresh oil and a new oil filter

Melett Turbo Tip – One of the misunderstandings regarding Insufficient Lubrication is there is no oil present in the turbocharger, this is incorrect, the oil

that is present is not enough to do the job required and will lead to the turbocharger failing.

Thank you for watching and we will see you next time for another Melett turbo tip video.

Enjoyed our Video? Press the like button, leave us a comment below or subscribe to our YouTube Channel to watch further videos from Melett.

Causes of insufficient lubrication

- Poor oil filter maintenance

- Insufficient oil in the sump

- Incorrect oil inlet gasket used leading to restriction in oil supply

- Build-up (coking) / carbon deposits in the oil feed pipe

- Applying silicone to the oil inlet gasket causing blockages

- Sludge or coke build up in bearing housing from hot shutdowns

- A damaged, blocked or low quality oil filter

- Failure to prime the turbo with oil before initial run

- Engine left idle for long periods, especially during cold weather

- Oil feed pipes containing bends or kinks

- Incorrect grade of oil is used

Signs of Insufficient Lubrication:

- Material transfer (caused by high temperature due to friction from bearings) to other thrust parts and the journal bearing diameter of the shaft and wheel

- Discolouration to the thrust parts and the journal bearing diameter of the shaft and wheel

- Excessive wear to the thrust pads of the thrust bearing

- Excessive wear to the journal bearings

Preventing turbo failure caused by Insufficient Lubrication:

- Oil supply to the turbo is critical, always check oil pressures are correct

- Always remember to prime the replacement turbocharger with oil before fitting

- Avoid using silicone on oil gaskets as they can easily become detached and block oil passages

- Clean or replace oil inlet pipes to remove carbon deposits or sludge that could restrict oil flow to the bearing systems

- Use fresh oil and new oil filters (which have been recommended by the engine manufacturer) when fitting a replacement turbocharger

- Allow time for the engine to warm up at the start of each journey and cool down at the end

TECH TIP – If the original cause of failure is not identified it is likely the same type of failure will occur on the remanufactured turbo. Insufficient Lubrication can result in catastrophic damage to the bearing systems which can occur within seconds of the turbocharger commencing operation.

For further information on this or other topics, please contact Melett Technical Support -.