RHF4/55 Bi-Metallic Thrust Washer Comparison

Lower Quality Sample (RHF4)

- No controlled scratches to create surface tension;

- Badly de-burred;

- Blackened colour;

- Pitted surface and edges – pitting can score the other thrust components and lead to premature failure;

- Doubts over the material quality?

Melett Sample (RHF4)

- Nice clean sharp bearing surface;

- Material is smooth, with controlled scratches on the surface;

- The surface is not scorched or pitted.

OEM Sample (RHF55)

- Clean, sharp edges, similar to the Melett sample;

- Controlled scratches on the surface.

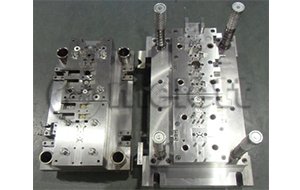

Tooling – RHF4 Bi-Metallic Thrust Washer (1450-040-321) tool

Melett invests heavily in our own tooling to ensure each part is precision manufactured to the correct tolerances and specification.

- The tool for the RHF4 Bi-metallic thrust washer is a very intricate tool;

- Made in Japan, the multi-stage press tool – starts with a strip of bi-metallic material (copper and steel), which then goes through 9 different stages to create the finished product;

- Producing the correct tooling requires significant investment and usually cost tens of thousands of pounds.

![]()

When you purchase a low quality core assembly, unless you dismantle each core it is unlikely that you will know the quality of the parts contained in that core before installing it.