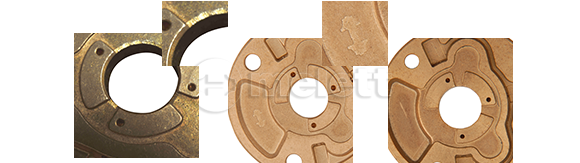

Component comparison – IHI RHF4/5 thrust bearings

Lower Quality Sample (RHF4)

To the untrained eye, initial impressions are that they look ok, however looking at the parts in more detail:

- The surface is very pitted – pitting can score the thrust parts and lead to premature failure;

- Badly de-burred;

- The edges are not clean and sharp;

- Often they have an over polished surface (focus is on aesthetics, rather than function);

- No controlled scratches to create surface tension.

Melett Sample (RHF4)

- Clean, sharp edges;

- Machined surface;

- No de-burring – when manufactured correctly this process is not a requirement;

- Performance mirrors the precision of the design;

- Controlled scratches to create surface tension.

When an engine is switched off overnight, if the surface is too smooth the oil will run off. The scratches create a surface to retain the oil and prevent run off, so when starting the engine in the morning there is already some oil present to lubricate the turbo.

OEM Sample (RHF55)

- Clean, sharp edges, similar to the Melett sample;

- Controlled scratches on the surface finish to retain oil.