Turbocharger specialist, Melett is warning the UK automotive industry to maintain quality as soaring raw material prices are seeing the cost of components rise.

The office for national statistics said that half of UK businesses reported a rise in the cost of materials, goods or services in March and with authorities, such as the DVSA, carrying out market surveillance on braking and emissions products in the past year, Melett is urging the sector to invest and continue down the path of high quality.

Nickel is the main element of the Inconel material used in the manufacture of turbocharger turbine wheels, as it can withstand the tough operating conditions and extreme temperatures of a modern turbocharger.

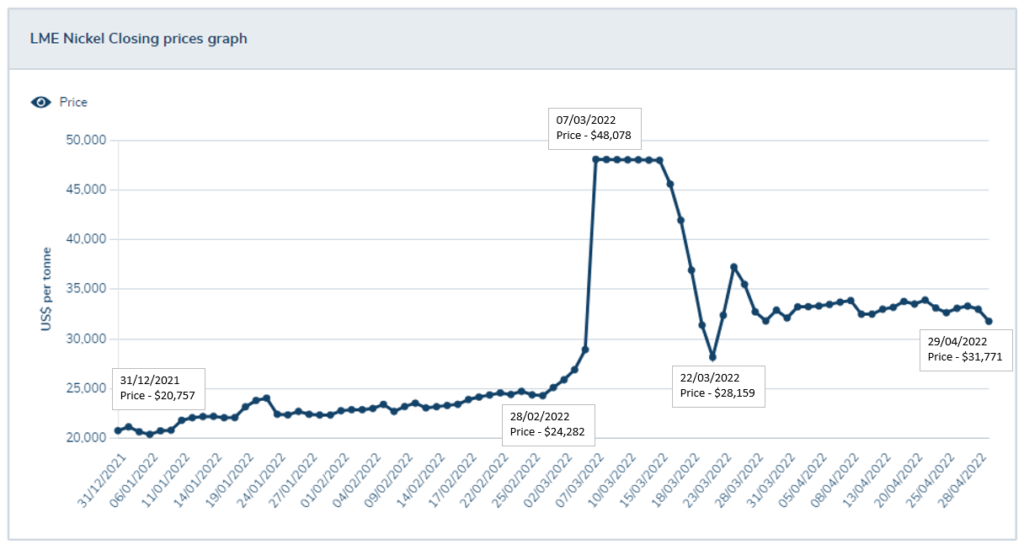

As shown in the below graph, during the month of March the cost of nickel increased by 100 percent overnight – from $24k / tonne to $48k / tonne – which caused the LME (London Metal Exchange) to halt trading of this commodity.

Following this historical record high, and although at the end of April the price had fallen back to $32k / tonne, this still represents an increase of 60 percent since the start of the year, where the price in January was $20k / tonne.

The biggest supplier of nickel is Russia and with the current conflict with Ukraine, coupled with the volatility in the raw materials market, as well as rising costs of labour, energy and transportation, prices of automotive components are increasing globally.

Andrew Frodsham, Melett Group Supply Chain Director, says: “Our investment over the years means we are able to operate a lean and effective supply chain, and in recent months we have increased and

enhanced our availability and manufacturing capabilities. With a dedicated team, we are best placed to work with customers as we navigate through the volatility within the market.”

Melett’s “What’s in Your Turbo?” initiative encourages the market to question part quality even more and look beyond price and appearance. The company says it is very risky to assume that parts are identical, even if they look the same.

It is important that the correct material grade is used in the manufacture of turbocharger parts. Premature turbocharger failure is a common problem associated with the use of lower quality repair parts, which can be as a result of using lower grade raw materials.

Melett understands the importance of using the correct materials and is committed to supporting the turbocharger repair market with the highest quality parts and service.